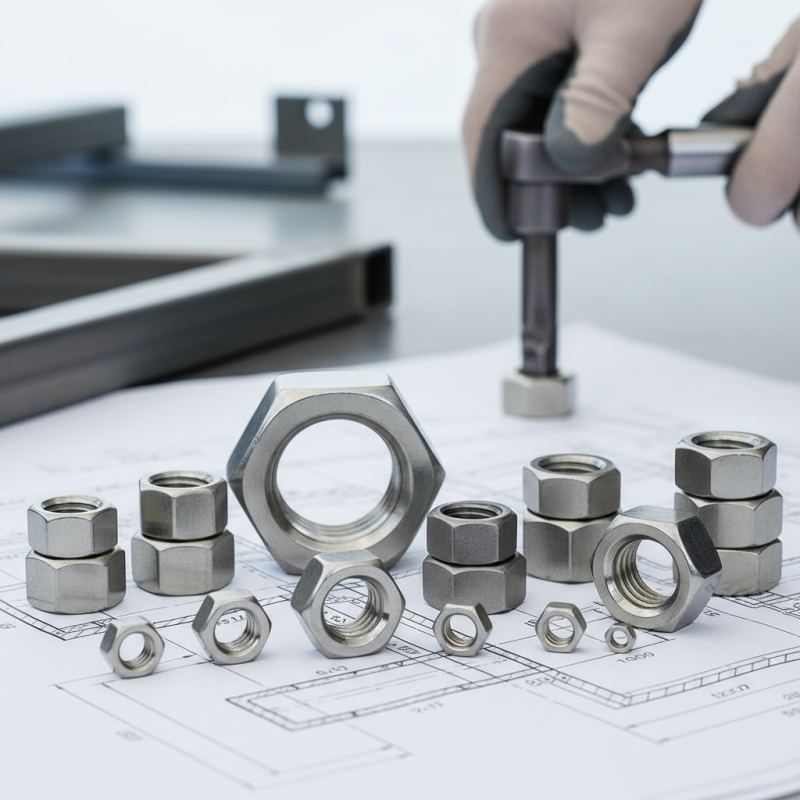

2026 How to Choose the Right Stainless Hex Nuts for Your Project?

Choosing the right Stainless Hex Nuts is crucial for any project. These fasteners play a significant role in ensuring strength and durability. According to industry reports, about 30% of structural failures can be traced back to improper fastening.

Stainless Hex Nuts offer resistance to corrosion and rust, making them ideal for various environments. A study showed that nearly 70% of engineers prefer stainless materials for outdoor applications. However, not all Stainless Hex Nuts are created equal. Different grades, sizes, and coatings affect performance.

It’s easy to overlook the specifications. Yet, even minor discrepancies can lead to major issues. Choosing the wrong type could result in structural weaknesses. Miscalculations in load-bearing capacity are common, which can be concerning. Proper research and understanding of your specific needs are vital. Remember, the right Stainless Hex Nuts not only enhance safety but also the overall success of your project.

Understanding the Different Types of Stainless Hex Nuts Available

Choosing the right stainless hex nuts is crucial for the success of any project. The wide variety of stainless hex nuts available can confuse even experienced professionals. These nuts come in different grades and materials, affecting their strength and corrosion resistance. Common grades include 304 and 316. According to industry reports, 316 grade is often preferred for marine environments due to its superior resistance to chloride corrosion.

Understanding the various types of stainless hex nuts can simplify your selection process. Standard, locking, and flange nuts each serve distinct purposes. Locking nuts prevent loosening caused by vibrations, which can be critical in dynamic applications. Flange nuts distribute load over a wider area. Misidentifying the type necessary can lead to project delays or failures. Many contractors underestimate the importance of selecting the right nut.

Actual projects show that using the wrong nut can result in significant costs. A case study revealed that construction delays can increase labor costs by up to 30%. It’s essential to pay attention to specifications and requirements for every project. Without careful attention, errors can tarnish the integrity of your work and lead to safety hazards. Attention to detail in selecting stainless hex nuts makes all the difference.

2026 How to Choose the Right Stainless Hex Nuts for Your Project?

| Type | Material Grade | Size (Diameter) | Finish | Strength (MPa) | Applications |

|---|---|---|---|---|---|

| Standard Hex Nuts | 304 | M6 | Plain | 580 | General use in construction |

| Lock Nuts | 316 | M8 | Black Oxide | 720 | Vibration-sensitive applications |

| Flanged Nuts | 304 | M10 | Zinc Plated | 500 | Automotive applications |

| Cap Nuts | 316 | M12 | Polished | 620 | Aesthetic finishes, plumbing |

| Wing Nuts | 304 | M5 | Natural | 450 | Easy hand tightening, furniture |

Key Material Considerations for Selecting Stainless Hex Nuts

When selecting stainless hex nuts, the material is crucial. Different grades of stainless steel provide varied performances in different environments. For instance, type 304 is versatile and resistant to oxidation, but may not withstand salty conditions. On the other hand, type 316 offers enhanced corrosion resistance, making it ideal for marine applications.

Tips: Always evaluate the environment where the nuts will be used. If exposure to chemicals or extreme weather is a concern, choose a higher-grade stainless steel. Remember, not all stainless steel is the same.

Another point to think about is the nut's strength. The tensile strength of the material affects the overall durability of your project. Selecting nuts with the right strength ensures reliability, especially under heavy loads.

Tips: Do a little research on the specific strength ratings you need. Sometimes choosing a weaker nut can lead to disappointing results. It's okay to seek help if you are uncertain.

Assessing Load Requirements and Their Impact on Nut Selection

When selecting stainless hex nuts, assessing load requirements is crucial. Load demands can significantly influence the type of nut chosen for a project. For instance, in high-stress applications, using nuts that can withstand significant tensile strength is vital. According to industry data, a typical stainless hex nut made from 304 stainless steel can handle loads of up to 70,000 psi. However, this varies depending on the specific design and the environmental conditions involved.

In real-world applications, excessive loads can lead to nut failure. It’s essential to factor in dynamics loads that may arise from vibration or movement. A study by the Fastener Technology Institute noted that nearly 20% of fastener failures result from improper load calculations. Missing these details might lead to project delays or increased costs. Always consider a safety factor, ideally at least 1.5 times, to prevent unexpected failures.

Material corrosion resistance is another essential factor. While stainless steel offers good resistance, specific grades outperform others under different conditions. For instance, in marine environments, grade 316 is often more effective than grade 304. This decision can have a profound impact on the longevity of a project. Balancing load requirements and material properties is not straightforward. Each choice carries potential risks and requires careful evaluation.

Exploring Coatings and Finishes for Enhanced Durability

When it comes to stainless hex nuts, the right coating and finish can significantly enhance durability. The choice of coating affects resistance to corrosion and wear. For instance, some coatings provide a sleek, smooth finish that helps prevent debris accumulation. This is crucial in environments where dirt and moisture can compromise performance.

Different finishes also offer varying levels of resistance. A powder-coated finish can provide excellent protection from environmental elements. It’s appealing, but it may chip under heavy stress. This is a key consideration when selecting hex nuts for high-load applications. On the other hand, a simple passivation treatment may not alter the surface much but can significantly boost corrosion resistance.

An important detail that often gets overlooked is the compatibility of coatings with the project materials. Mismatched materials can lead to galvanic corrosion. Awareness of this potential issue is essential for long-term success. Consideration should also be given to the specific environment. Will your project face extreme temperatures or harsh chemicals? Evaluating these factors will guide you toward the best choice for durability.

Tips for Sourcing Quality Stainless Hex Nuts for Your Project

When sourcing quality stainless hex nuts, consider material grade carefully. The most common grades are 304 and 316. Grade 304 offers good corrosion resistance and is often sufficient for indoor projects. However, for outdoor or marine environments, grade 316 is superior. It includes molybdenum, providing extra protection against pitting. According to a 2022 industry report, the corrosion resistance of 316 can increase lifespan by over 50%.

Quality control is another critical factor. Verify that the manufacturer follows industry standards. Look for ISO certifications when selecting suppliers. The ASTM standard indicates a reliable quality benchmark. A 2021 survey revealed that 30% of projects experienced delays due to sourcing low-quality fasteners. Inadequate inspection can lead to significant failures.

Don’t overlook the importance of proper sizing. Mismatched sizes can cause functional issues in your projects. Ensure you have precise measurements before placing orders. Additionally, consider sourcing from multiple suppliers to compare quality. A single supplier might not provide consistently high-grade products. Balancing cost and quality is essential. Sometimes, a cheaper option may save money but lead to complications later. Reflecting on current practices can guide improvements in future sourcing strategies.