Why is a Damper Actuator Important for HVAC Systems?

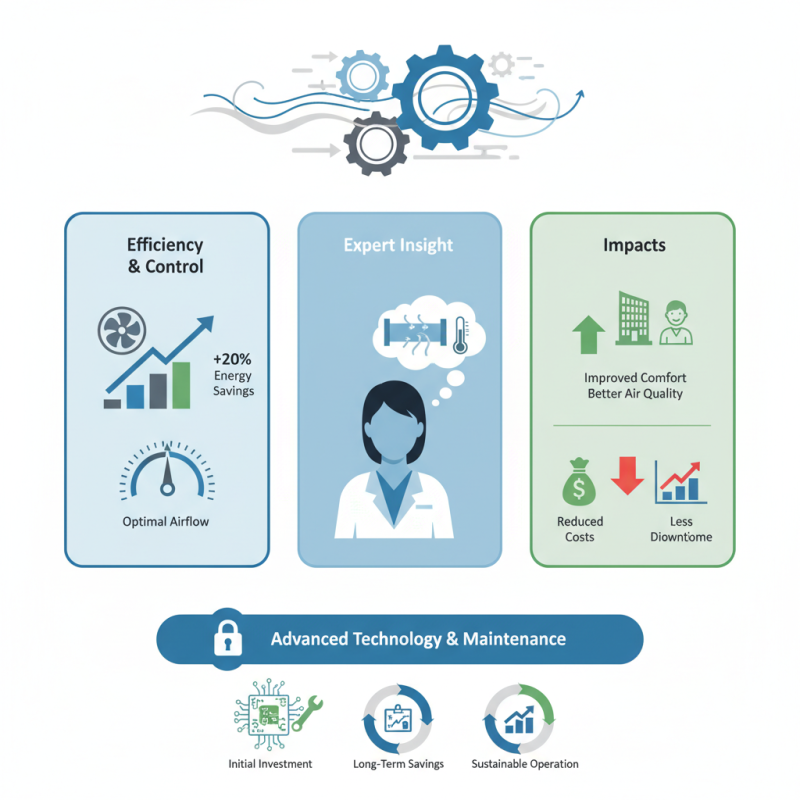

In the realm of HVAC systems, efficiency and control are paramount. The Damper Actuator plays a crucial role in this process. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), HVAC energy efficiency can improve by over 20% with optimal damper actuator performance. This highlights the importance of understanding and utilizing these devices effectively.

Industry expert Dr. Emily Tsai emphasizes, "A well-calibrated damper actuator is essential for achieving the desired air flow and maintaining comfort in indoor environments." The damper actuator controls airflow through ventilation ducts, impacting both energy consumption and indoor air quality. Neglecting its maintenance can lead to inefficiencies and rising operational costs.

Despite their importance, many HVAC systems still employ outdated or improperly configured damper actuators. This oversight can reduce system efficiency and comfort levels. Investing in advanced technologies and regular maintenance is critical. It's a challenge that requires ongoing attention. The choice of the right damper actuator impacts both immediate comfort and long-term operational costs.

Understanding the Function of a Damper Actuator in HVAC Systems

In HVAC systems, a damper actuator plays a crucial role. It helps control airflow throughout a building. These devices adjust the position of dampers, which regulate air movement. When the demand for heating or cooling changes, the actuator responds. It opens or closes the damper to optimize airflow.

The effectiveness of heating and cooling relies on these adjustments. A well-functioning actuator ensures even temperature distribution. On the other hand, if the actuator fails, problems arise. Inefficient airflow can lead to hot and cold spots. Energy consumption may increase, driving up utility costs.

Regular maintenance of damper actuators is essential. Dust and dirt can hinder their performance. Neglect can result in costly repairs or replacements. Users should monitor signs of malfunction. This awareness can prevent bigger issues in the long run.

Key Benefits of Using Damper Actuators for Airflow Control

When it comes to HVAC systems, damper actuators play a crucial role in managing airflow. These devices adjust the position of dampers, which control how air moves through ductwork. Without them, achieving optimal airflow is challenging. Variable airflow can lead to uncomfortable temperatures in different rooms. It can also increase energy bills unnecessarily.

One of the key benefits of using damper actuators is precision. They allow for fine-tuned adjustments, enhancing efficiency. Improved airflow leads to uniform temperature distribution. This means fewer cold spots and warm pockets in a building. However, some may overlook their importance. A simple damper malfunction can disrupt an entire system.

Another advantage is automation. Many modern systems integrate damper actuators with smart technology. This allows for real-time adjustments based on environmental conditions. Yet, reliance on automation has drawbacks. If not monitored, it can lead to over-adjustment or damage. Understanding how these components work together is essential for long-term efficiency.

Types of Damper Actuators and Their Applications in HVAC

Damper actuators play a crucial role in HVAC systems. They control the airflow within ducts, helping to maintain desired temperatures and air quality. There are two main types: electric and pneumatic. Electric actuators are more common. They offer precise control and faster response times. Pneumatic actuators use compressed air, often found in older systems.

In modern HVAC applications, electric actuators are preferred for their efficiency. Reports indicate that they can reduce energy consumption by up to 30%. This is significant in large commercial buildings. Their size and complexity vary based on the application. Some actuators are used for variable air volume systems, while others may serve isolation functions in fire and smoke dampers.

However, the choice of damper actuator often lacks proper analysis. Many systems continue to use outdated technology. This can lead to inefficiencies and increased operational costs. Real-time monitoring can address some pitfalls. Yet, investment in advanced actuators may be overlooked. This can be a missed opportunity for better control and energy savings in HVAC systems.

Installation Considerations for Damper Actuators in HVAC Systems

When installing damper actuators in HVAC systems, proper placement is crucial. This ensures efficient airflow and temperature control. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), appropriate actuator selection can increase energy efficiency by 20-30%. Ensuring that actuators are correctly matched to duct size and type enhances performance significantly.

Tips: Consider the torque requirements based on the damper size. This will prevent actuator failure and ensure responsiveness.

Specific attention to actuator type is essential. Different environments, like humid conditions, require specific materials for durability. A report by the Energy Information Administration (EIA) states that over 40% of HVAC operational failures stem from improper component specification.

Tips: Always check compatibility before installation. Using actuators designed for specific environments can save costs in the long run.

Lastly, installation angle should be accounted for, especially in vertical applications. A misalignment can lead to inefficiencies. Many installations overlook this detail, leading to wasted energy and increased wear.

Maintenance Tips for Ensuring Optimal Performance of Damper Actuators

Damper actuators play a vital role in HVAC systems. They help control airflow and maintain temperature balance. Regular maintenance is crucial for their efficiency. Neglecting this can lead to malfunction and increased energy costs. According to industry reports, poor actuator performance can raise energy consumption by 30%.

To ensure optimal performance, inspect the actuators quarterly. Look for signs of wear or corrosion. Dust and dirt can accumulate on the moving parts. Clean these areas to prevent jams. Be aware that a stuck actuator can interfere with system balance. Replace outdated actuators promptly to avoid inefficiency.

Lubrication is essential. Applying the right lubricant will keep components moving smoothly. However, over-lubrication can lead to additional issues. Monitor actuator response times closely. Delays can indicate underlying problems. Address these issues swiftly to maintain system integrity. Neglect will only compound the issues. Regular checks and timely interventions can keep your HVAC system running smoothly.