Ultimate Tips for Choosing Sandblast Rubber Hose?

Choosing the right Sandblast rubber hose is crucial for effective and safe sandblasting. A well-chosen hose improves performance and durability. It can withstand abrasive materials and intense pressure. However, not all hoses are created equal.

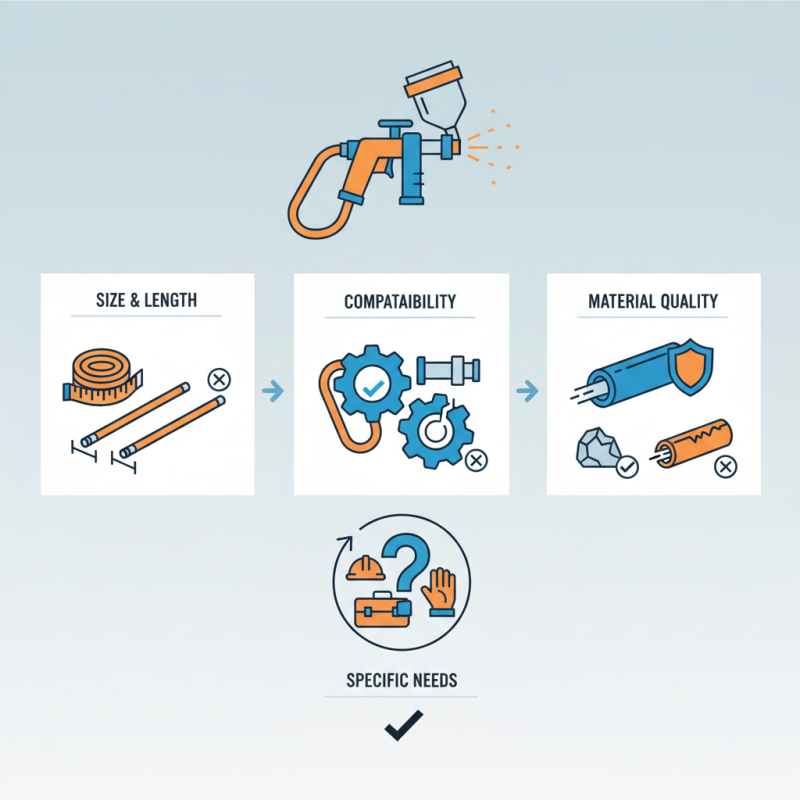

Consider the size and length when selecting a sandblast rubber hose. Too short, and you may struggle to reach your work area. Too long, and you risk losing pressure. Pay attention to compatibility with your equipment. Mismatched hoses can lead to costly damages.

Additionally, examine the material quality. A durable hose can last longer and resist wear. Look for features like abrasion resistance and flexibility. Sometimes, people overlook details, leading to poor choices. Reflect on your specific needs to make the best decision.

Understanding the Basics of Sandblast Rubber Hoses

When selecting a sandblast rubber hose, understanding its components is vital. These hoses are designed to withstand high pressure and abrasive materials. A proper hose is essential for effective sandblasting operations. Pay attention to the inner diameter, as it impacts flow rate. A larger diameter can carry more materials but may require more pressure.

Material quality is another crucial factor. Rubber hoses should be durable and flexible. Low-quality hoses can kink and lead to blockages. Look for hoses that offer both resistance to wear and a good bend radius. Checking the hose's temperature rating is also important; a hose that cannot handle heat may fail unexpectedly.

Consider the length of the hose as well. Longer hoses can limit mobility; too short may hinder performance. Make sure to think about your workspace layout. A hose that matches your specific needs will always deliver better results. Remember, it's okay if it takes time to find the right fit. Reflect on what has worked for you before, and be open to adjusting your choices.

Key Materials Used in Sandblast Rubber Hose Construction

When selecting a sandblast rubber hose, the key materials in its construction greatly affect performance. Most hoses are made from natural and synthetic rubber. These materials provide flexibility and durability under extreme conditions. According to industry reports, hoses made from high-quality rubber can withstand temperatures ranging from -30°F to 200°F without losing structural integrity.

Additionally, reinforced materials are often used. Textile layers or steel wires enhance strength and resistance to abrasion. Data shows that hoses with such reinforcements last up to 30% longer under heavy use. However, not all materials are created equal. Some cheaper alternatives may appear appealing, but they often lead to premature wear and tear, resulting in costly replacements.

Another consideration is the hose's inner lining. A poor lining can lead to blockage and fluctuating pressures, negatively impacting efficiency. Engineers recommend checking specifications and testing inner diameter compatibility as well. Small decisions here can lead to significant differences in overall sandblasting efficiency. The right choice in materials shapes not just the performance but also the longevity of your equipment.

Factors Affecting the Performance of Sandblast Rubber Hoses

When selecting a sandblast rubber hose, consider various performance factors. The material's quality plays a significant role. High-quality rubber can resist abrasion better. This means a longer lifespan for the hose. Additionally, flexibility is crucial. A flexible hose can maneuver easily, reducing the risk of kinks and breaks.

Another essential aspect is the hose's diameter. A larger diameter can allow for greater airflow. However, it may add weight. In contrast, a smaller diameter is lighter but may restrict airflow. It’s important to find a balance based on the specific application needs. Evaluate your requirements carefully.

Tips: Always check the hose's pressure rating. Ensure it meets your project demands. Inspect the hose regularly for signs of wear. Look for cracks or soft spots; these can indicate issues. An abrasive environment will wear down hoses faster. Be prepared to replace them sooner than expected. Always err on the side of caution when it comes to safety.

Tips for Proper Maintenance of Sandblast Rubber Hoses

Proper maintenance of sandblast rubber hoses is crucial for optimal performance. Regular inspection is key. Look for cracks or wear on the hose exterior. A small crack can lead to bigger issues. If the outer layer is compromised, air pressure may escape. This can affect efficiency.

Storage also plays a vital role. Keep hoses in a cool, dry place. Avoid leaving them in direct sunlight. Constant exposure can degrade the rubber. Coiling hoses properly helps prevent kinks. Kinks can restrict airflow and create weak points. It's easy to overlook these details, but they matter.

Cleaning is essential after use. Sand and debris can damage hoses. Rinse them with water to remove residues. Be careful not to use harsh chemicals, as they may cause deterioration. Maintaining a regular cleaning schedule can prolong the hose's life. Ignoring these steps can lead to replacement sooner than expected.

Common Applications for Sandblast Rubber Hoses in Industry

Sandblast rubber hoses are essential in various industries. These hoses are designed to handle high-pressure and abrasive materials. Construction, mining, and manufacturing often rely on these hoses for effective operations. For example, in construction, sandblast hoses aid in the cleanup of surfaces. They play a key role in preparing buildings for painting or coating.

Selecting the right hose is crucial. Consider the material. Rubber hoses can withstand extreme conditions. Look for hoses that resist wear, tear, and abrasion. This ensures durability and longevity. Testing the hose's resistance to chemicals is beneficial too. A little oversight here can lead to damage.

Applications extend beyond construction. In automotive repair, these hoses help in surface preparation for painting. They effectively remove rust and old paint. However, using a lower-quality hose might result in leaks. This can disrupt operations and increase costs. Choosing a suitable hose will always pay off in the long run.